Solutions

At PPS Automation we offer all types of solutions, both standard and customized,

within automation and robots.

Welcome to Industry 4.0 – also called the Fourth Industrial Revolution.

Custom-built automation solution

At the R-22 robotic fair in Odense in March 2022 we showcased one of our latest automation solutions, specially designed for Resino Farver.

The solution includes depalletizing of buckets using a UR10e robot, after which full-color labels are printed and applied directly to the buckets. This solutions is unique because we inline print the full label layout in colors based on information received from the customer’s ERP system. Then the label is applied to a conical bucket and the bucket is placed on a feed conveyor belt on the customer’s filling line.

Solution based on prototype

Five years ago, Tojos Plast contacted PPS Automation for help with a new automation solution. They had a customer with unique needs and was therefore considering investing in a machine that could assemble and label multiple components in the same proces.

It was a completely new project, so everything had to be developed from scratch. PPS suggested to build a prototype to determine the actual needs. It turned into a good proces, where one specialized, yet flexible solution was iteratively developed, which fulfilled all needs. At the same time, the solution can be changed and further developed in the future.

Read the full case story here and learn more about the solution.

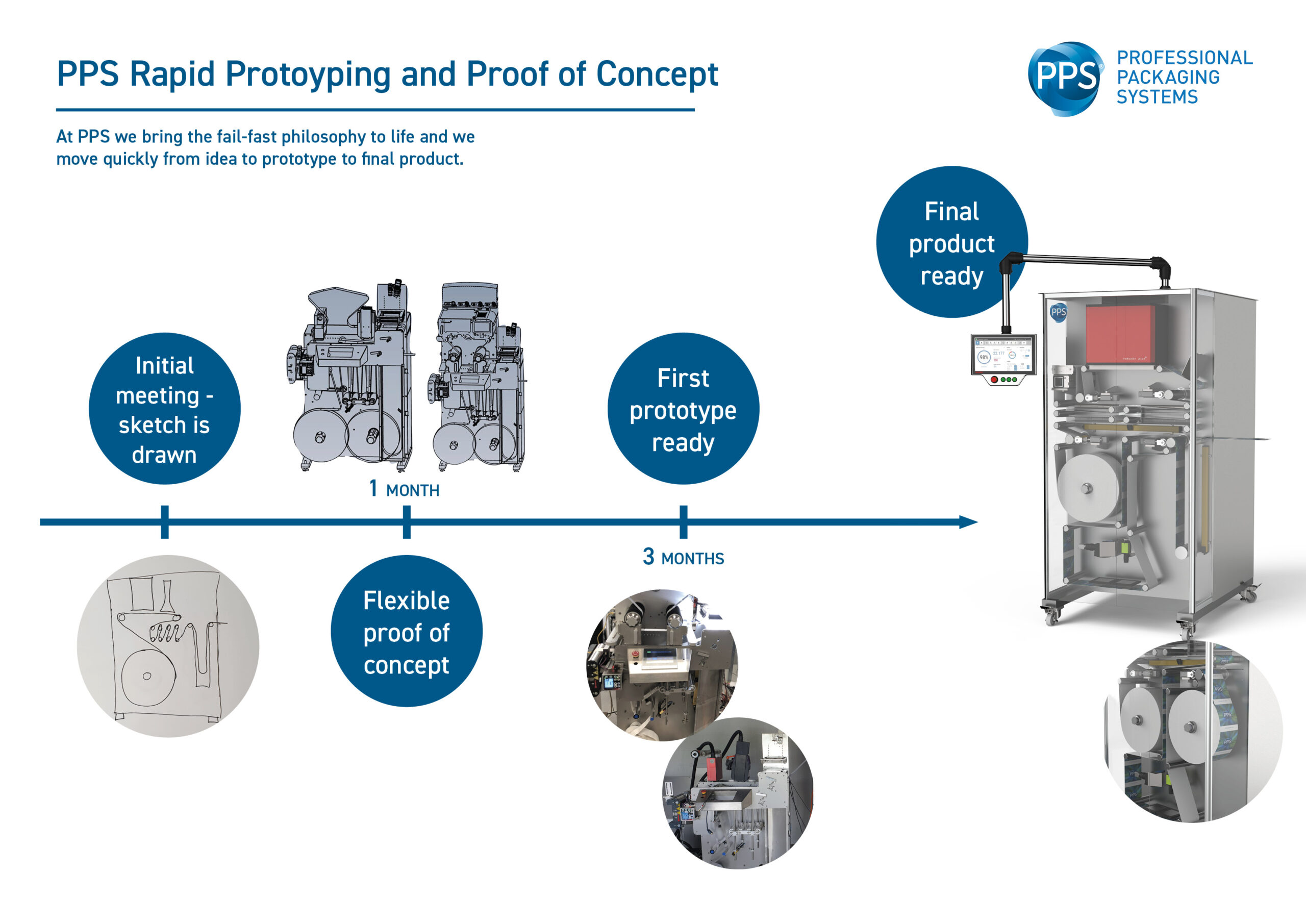

Prototypes

We like to work according to the “Fail fast” philosophy, which means that we quickly and efficiently build a protoype where new technology can be tested, before a decision on implementation on a larger scale is made.

If the model does not meet the set success criteria, we will keep on developing the solution based on the learnings we have from the protoype. In this way, we avoid a long process of analysis, design and testing, and can instead test a number of different solutions quickly and efficiently.

We are not afraid to make mistakes, as the mistakes are valuable learnings, which helps us to find any challenges faster and adapt the solution.

Proof of Concept

In the same way, we have extensive experience in developing Proof of Concept studies, which typically invovles us designing a solution and testing it on a smaller scale, before deciding whether it should be rolled out on a large scale.

Your investment will be limited and your business case will be tested to see if it is sustainable and supports your business goals. That way, you will quickly get an answer on whether the solution is the right one, before you possibly present it to the management or implement it in your company.

We offer solutions from

Universal Robots

Universal Robots started in 2005 i Copenhagen with the vision tof making robot technology accessible to small and medium-sized companies. Their easy-to-use and advanced robotic arms are used today by campanies and organizations of all sizes and make it possible to help and meet the changeble market. We are Universal Robots certified system integrator, CSI, in Denmark and we can hereby document out competencies within the UR-technologies.

Denso Robotics

Denso Robotics is a global company with more than 60 years of experience. Denso offers a wide range of 4-axis SCARA and 5- and 6-axis industrial robots with payloads up to 20kg. All robots operate with the highest precision and high speed. Standard models, dust- and moisture resistant models. as well as robots for cleanrooms are options that can be used for many different applications.

Partners

We work toegther with a number of recognized and specialized partners, who each excels within their field. Read more about our partners here.

References

We have implemented solutions within automation and process optimization for a large number of customers, including Novo Nordisk, FujiFilm and Biogen.

News

Follow the latest news and get the latest knowledge about technology, insights from cases, invitations to events and news about relevant subjects within the industry.