Automation solution for Tojos Plast

Tojos Plast is a Swedish company with more than 70 years of experience in producing plastic items in customized solutions and various designs. As a wide range of solutions is offered in relation to both materials, shapes and colors, flexibility is key for the company.

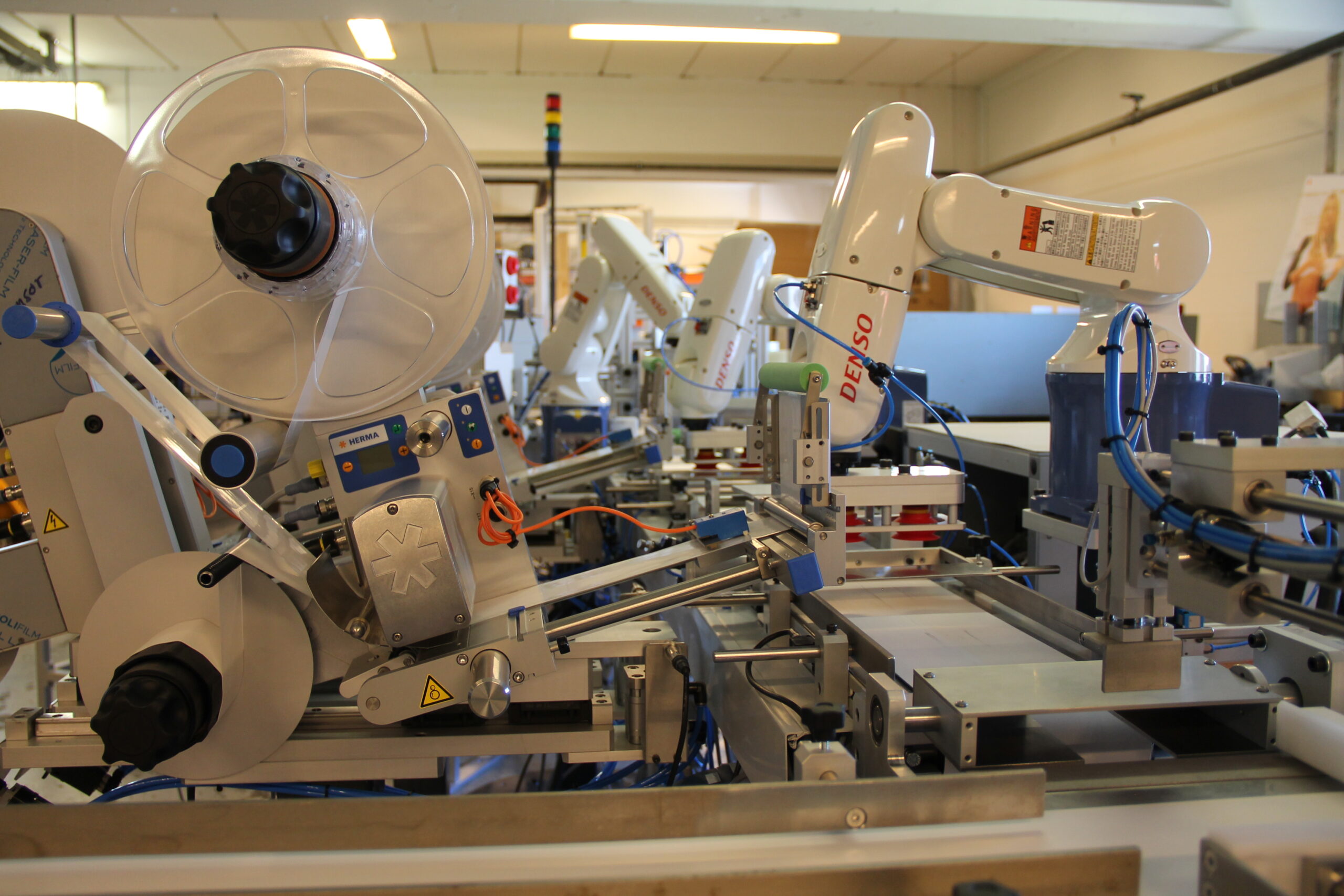

Five years ago, Tojos Plast contacted PPS Automation for help with a new automation solution. They had a customer with unique needs and was therefore considering investing in a machine that could assemble and label multiple components in the same proces. It was a completely new project, so everything had to be developed from scratch.

PPS suggested to build a prototype to determine the actual needs. It turned into a good proces, where one iteratively developed one specialized solution with the following steps:

- An injection molded box with contents is assembled

- Variable data is printed on the label

- The box is labelled on the front and back

- The boxes are stacked in 5 pieces. A shipper box is erected

- 5 boxes is packed in every shipper box

- The shipper box is closed

During the work with the prototype, small problems were discovered early and taken care of. For example, small air bubbles appeared under the labels. PPS changed the design and eliminated the issue. This meant that there were no small errors and lack of adjustments when the equipment was installed in production.

Full utilization

Along the way, PPS came up with suggestions for optimizing the proces, which took advantage of the fact that the object was oriented and in a defined position in the robot’s gripper.

This meant that the proces was extended so that the batch number could also be printed on the label, an extra label could be added and the items could be packed in boxes.

These were all processes that were previously carried out manually by operators. This means that one automation solution now solves several needs simultaneously.

”With PPS, we found out what we actually needed. The process with a prototype worked really well. Both we and the customer were able to change things and we got the perfect solution.

Watch a short video of the automation solution for Tojos Plast.

Flexible solution

Tojos Plast’s customer had changing needs. During the process, all parties learned about their own needs and how it could be automated best. The customer saw the new possiblities in the setup developed by PPS and Tojos Plast.

PPS Automation’s advice made it possible to develop a specialized but flexible solution that met all needs. At the same time, it can be changed and further developed in the future.